This year we are celebrating the centenary of the birth of Arthur Hollins who was born in May 1915. From 1928 onwards Arthur and his Mother used the milk from their Dairy Shorthorns to make cream cheese, Cheshire cheese and other traditional dairy products. During the Second World War they were restricted to selling liquid milk to the government who used it to make dried milk and the official ‘Government Cheddar cheese’. After the war ended Arthur found selling his liquid milk and the few organic vegetables they produced during the following nine years was not enough to keep him and his family. He started to plan ahead and even before the end of restrictions and rationing in 1954 he had sold the Dairy Shorthorns and had started to build up his herd of Fordhall Pedigree Jerseys.

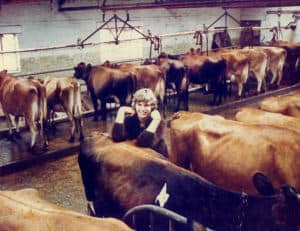

By 1956 Arthur already had the cows needed to provide the milk for clotted cream and cream cheese production. As the herd grew so did the dairy business with yoghourt, yoghourt cheese and cottage cheese production in full swing by 1958. By 1961 the herd numbered about 100.

As soon as TB testing in cattle started in the late 1950s Arthur was quick to realise the importance of having his herd tested. He was therefore able to advertise his herd as Fordhall Pedigree TT Jerseys (TT meant Tuberculin tested). This gave his customers confidence in the safety of his dairy products.

Arthur also made changes to the milking parlour and the way he collected the milk. In around 1956 Arthur adapted an early milking machine to milk four cows at once instead of the usual one. He even devised a system to carry the milk straight from the milking parlour to a separating chamber in the dairy which improved hygiene in the dairy. Arthur later on turned the shippon into a modern milking parlour. He also helped develop the herringbone milking parlour which was much more efficient and hygienic.

The way Arthur kept his cows was also important. He developed his ‘foggage’ system where the cows were kept outside all year including the winter on the organically grown pasture. According to Arthur in an experiment where some cows were taken in during the winter and others kept out, the cows which were kept outside did not suffer any problems. Their milk yield did not suffer and they were much healthier and went to the spring grass better than those kept inside.

In the late 1970s with increasing competition from mass-produced cheaper dairy products, Arthur decided to gradually close down his dairy business and concentrate on the organic meat trade. He moved on to a mainly Hereford herd and Arthur later teamed up with Ray Cornmell, a family butcher from Bolton, who sold Arthur’s organic meat on market stalls in places like Newcastle-under-Lyme and Altrincham. Ray also sold the organic meat in his shop in Bolton and at the farm shop. He was also a wholesale supplier to hotels and restaurants, and also took orders over the phone and sent the meat vacuum packed for next day delivery.

After the Farm was saved from extinction in 2006 Ben took over where his father left off. As he explains on his webpage, “I am carrying on my late father’s philosophies of organic production, whilst learning my own new ways of improving Fordhall. Our outdoor reared cattle graze on our organic pastures through winter and summer with no additional grains (otherwise known as Foggage Farming). All Herefords and Aberdeen Angus, our traditional herd is hardy and accustomed to living outdoors they have thick coats to cope with winter weather and all are registered organic with the Soil Association. We rear all our own beef from birth to death and we even have our own pedigree Aberdeen Angus Bull ‘Woody’, so no need for artificial insemination!”

To read more about ‘Ben Hollins’, tenant farmer at Fordhall Organic Farm click here.

To read more about the animals, click here.

To order produce from the on-line shop click here.